Mechanical &

Contract

Engineering

Mechanical Surface Finishing

For over 30 years, Bartholet Ropeways AG has been supplying high-precision components made of stainless steel and specialized aluminum alloys for products used in vacuum processes. In these industries, cleanliness, appearance, durability, and dimensional accuracy are essential. To meet these demanding requirements, Bartholet employs specialized surface finishing processes.

We use automated deburring, rounding, and scale removal with grinding and brushing machines to prepare steel components for the coating process.

Glass bead blasting produces a uniform metallic, silvery-diffuse finish. By using small bead sizes of only 60–200 µm, abrasion is prevented and the components retain their dimensional accuracy. The surface-hardening effect is an additional, beneficial result of the process.

Tumbling, or vibratory finishing, is carried out using a vibration trough filled with ceramic media. Aluminum or stainless steel components processed in this way achieve a clean, bright surface finish.

For aluminum or stainless steel components, we offer polishing or ball polishing. In ball polishing, balls and pins are used in a vibration trough. This process allows aluminum parts to achieve very fine surfaces with low roughness values, resulting in dense, smooth, and glossy finishes.

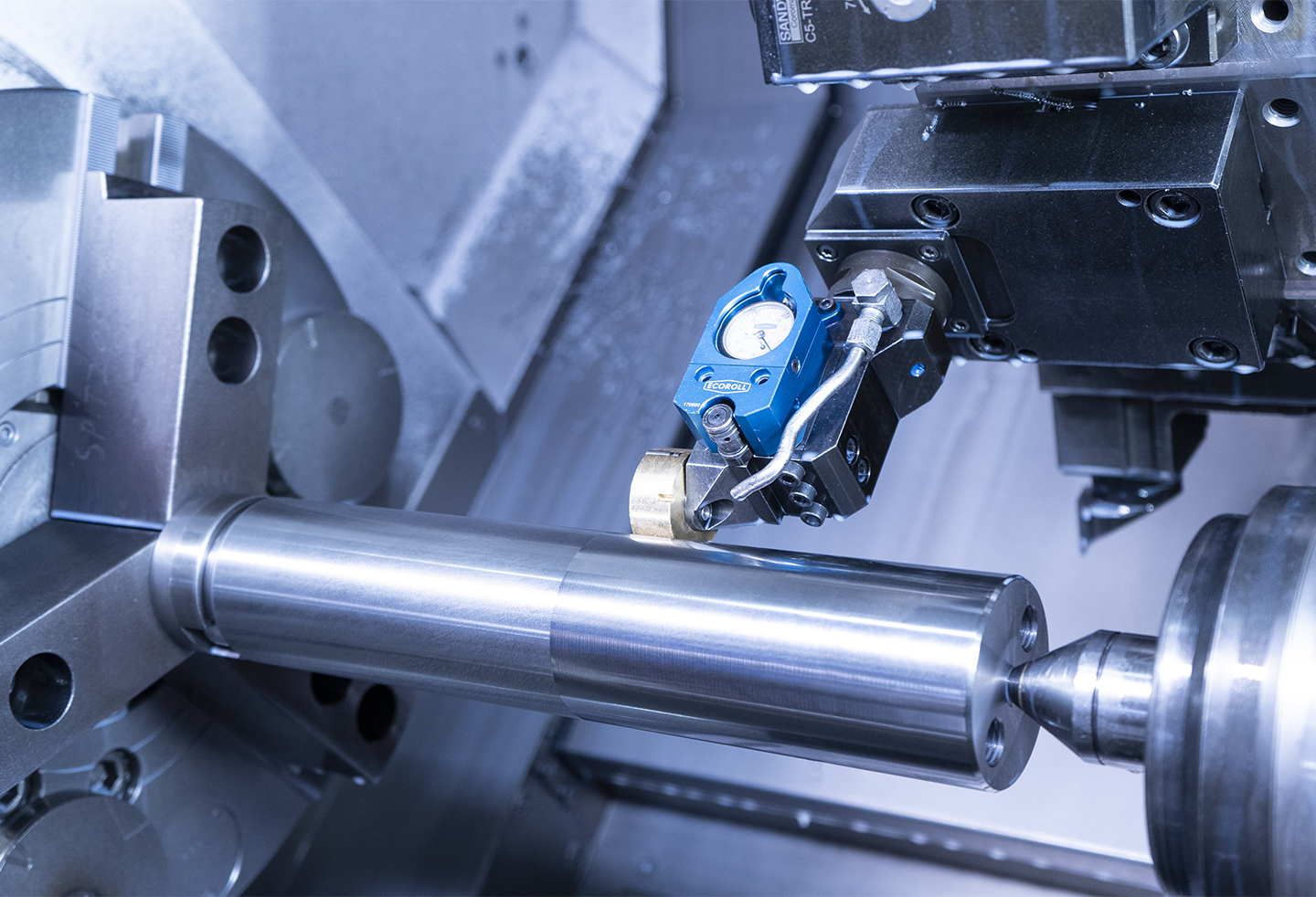

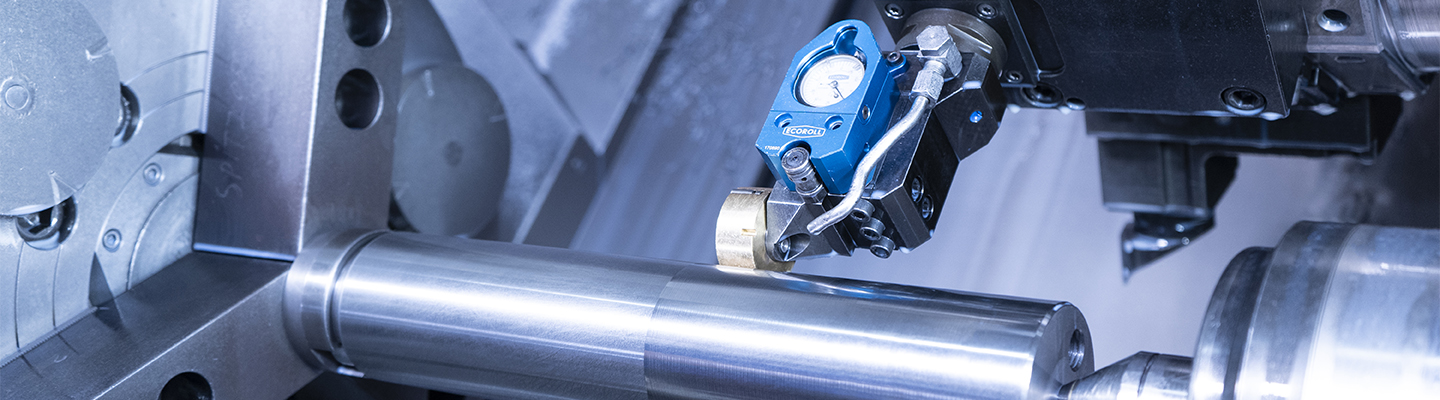

The roll finishing process allows surface parameters of turned parts to be produced reproducibly. Bartholet achieves a surface roughness of Ra < 0.2, eliminating the need for post-chroming polishing.

Stainless steel or aluminum components can achieve cleanliness level 1 through thorough and gentle cleaning in ultrasonic baths at 40 kHz and 80 kHz. This ensures a brilliant finish for parts that are subsequently used in vacuum applications, ranging from the semiconductor industry to medical technology.